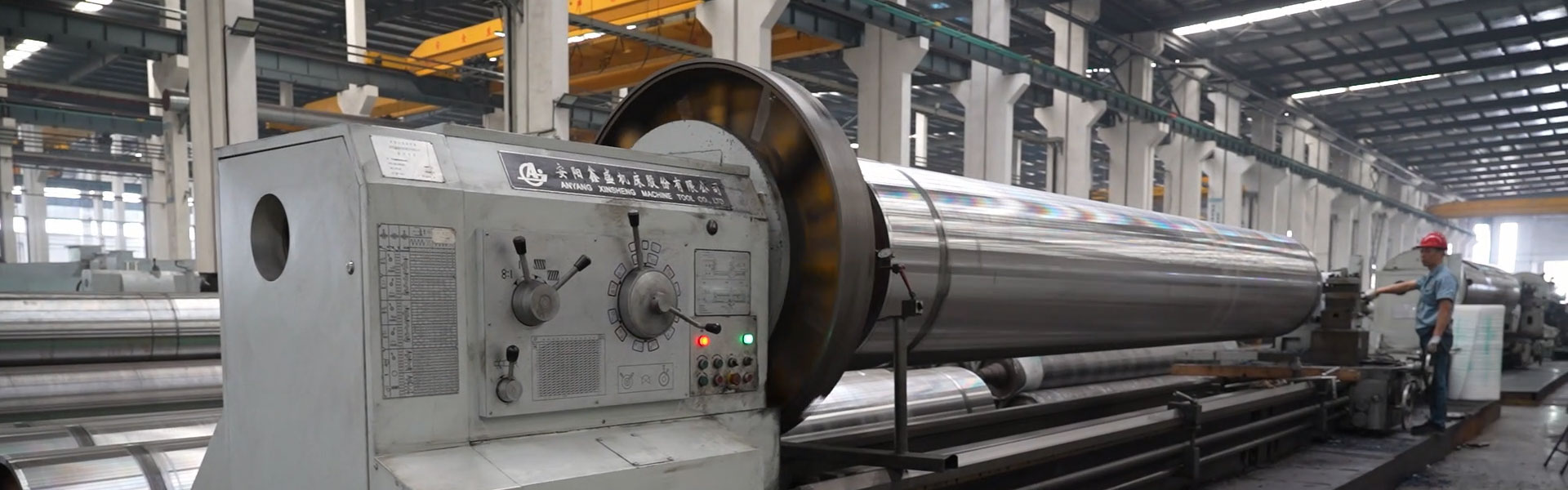

Roll paper processing equipment

Roll paper processing equipment is a specialized machinery used to process metal (such as steel, aluminum) or composite material blanks into roll paper rolls (used to support and transport paper) required by industries such as papermaking, printing, and packaging. Its core function is to achieve pre......

Send Inquiry

Product Description

Roll paper processing equipment is a specialized machinery used to process metal (such as steel, aluminum) or composite material blanks into roll paper rolls (used to support and transport paper) required by industries such as papermaking, printing, and packaging. Its core function is to achieve precise forming and surface treatment of the roll body. The paper roll has extremely high requirements for dimensional accuracy (diameter tolerance ± 0.01mm) and surface quality. The equipment needs to have a precision transmission system (such as ball screws, servo motors) and real-time error compensation function to ensure that the processed roll body is free of defects such as ovality and taper. For different materials of roller bodies (such as steel rollers and aluminum rollers), the equipment will optimize the processing technology. For example, special cutting tools will be used to reduce deformation during aluminum roller processing, and the electroplating current will be adjusted during steel roller surface treatment to ensure uniform coating.